Work Departments

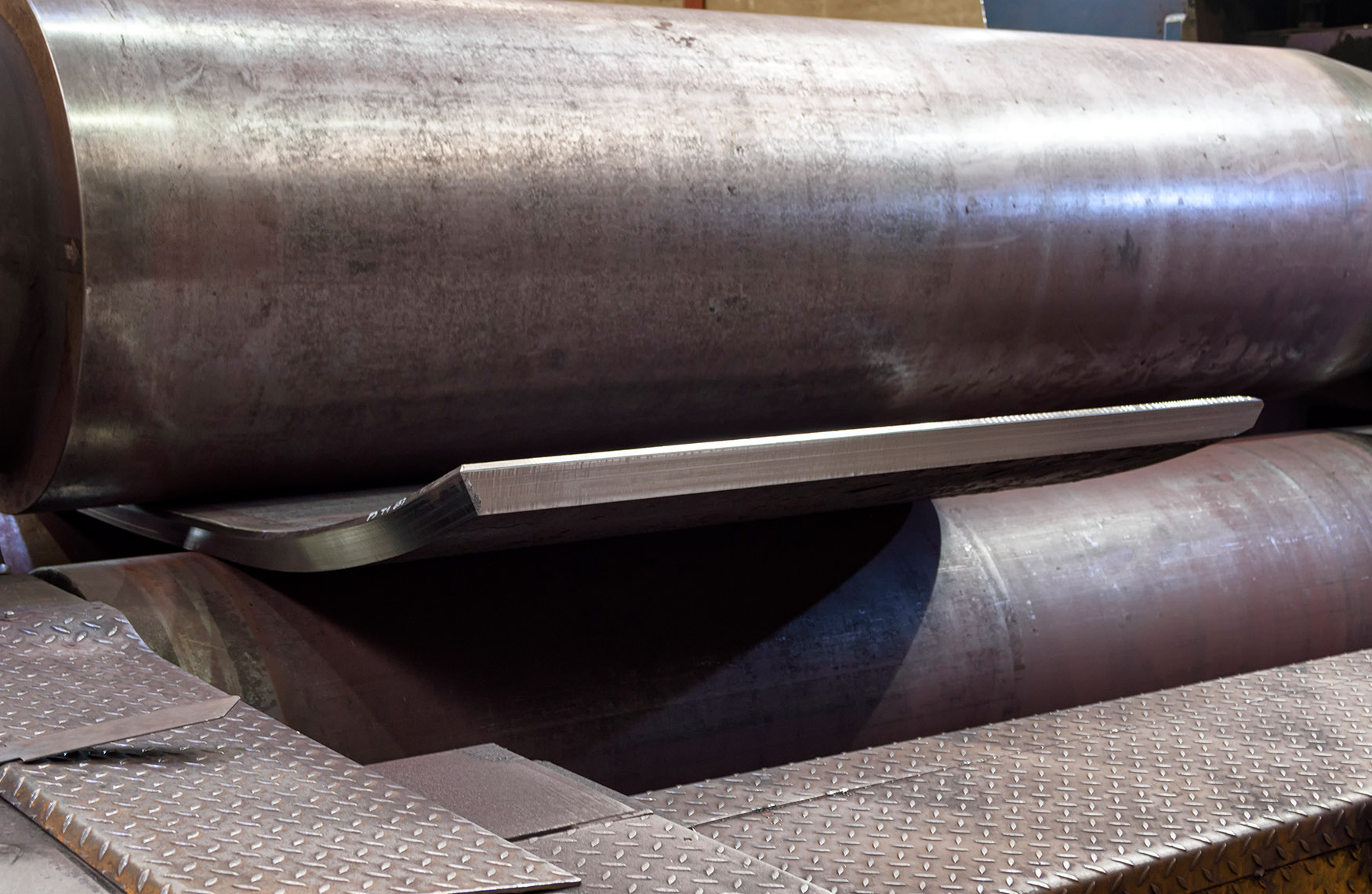

Cutting and Bevelling department

Since 2017, the sheets preparation (cutting and bevelling) process, as a pre-construction task, has been taken over by Eiffage Metal as part of a vertical integration process, improving its control and efficiency.

Para la realización de este, se disponen de:

Metal Parts Construction department

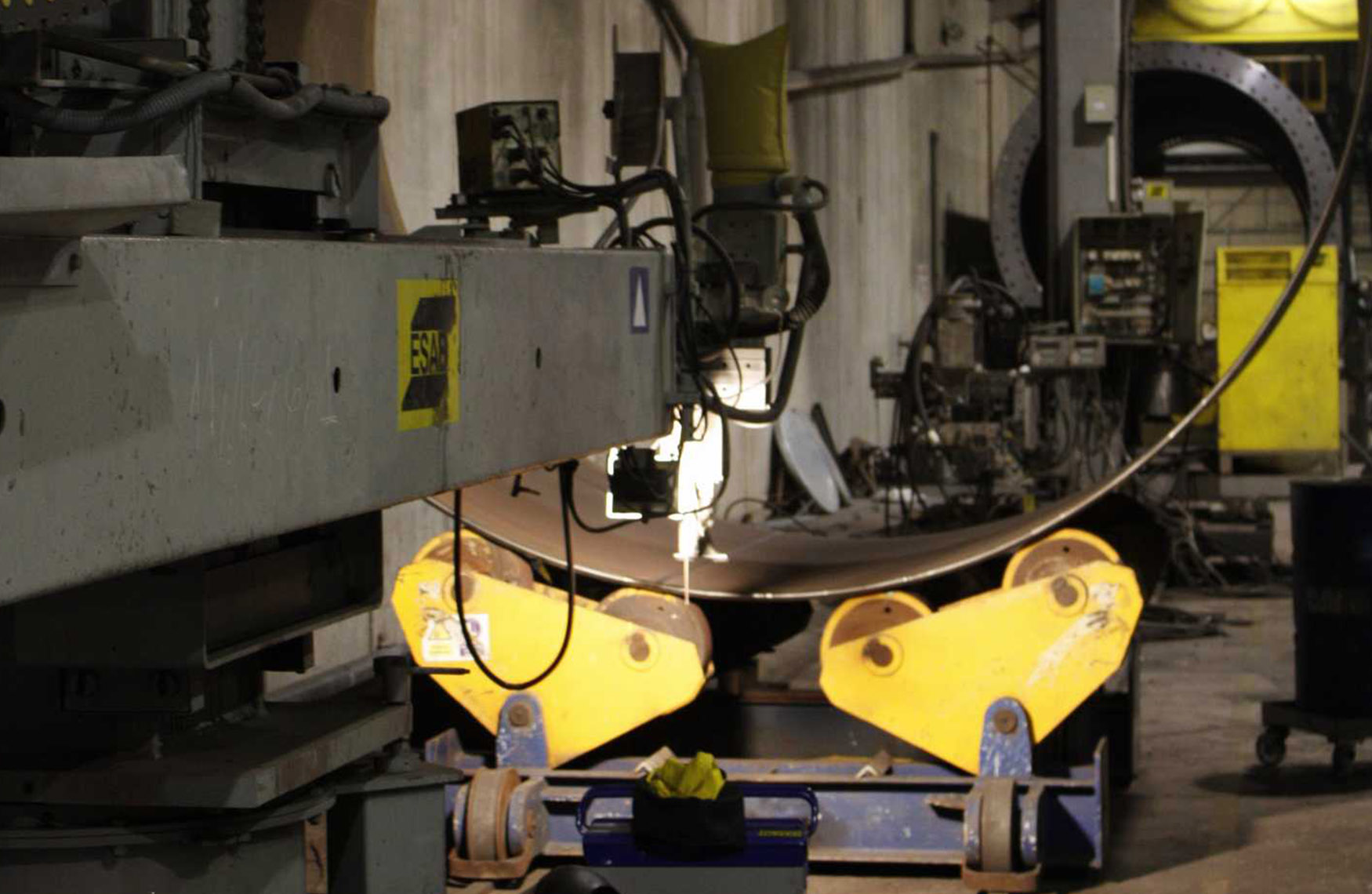

Once the sheets have been cut and bevelled, these are then subjected to the section bending and welding process.

Bending machines:

Welding machines

Surface Treatment department

Once the boilermaking works are finished, it is the turn of the metallisation (whenever necessary), shot blasting and painting process.

Having 3 shot blasting cabins:

4 paint booths:

Other processes: